PRODUCTS

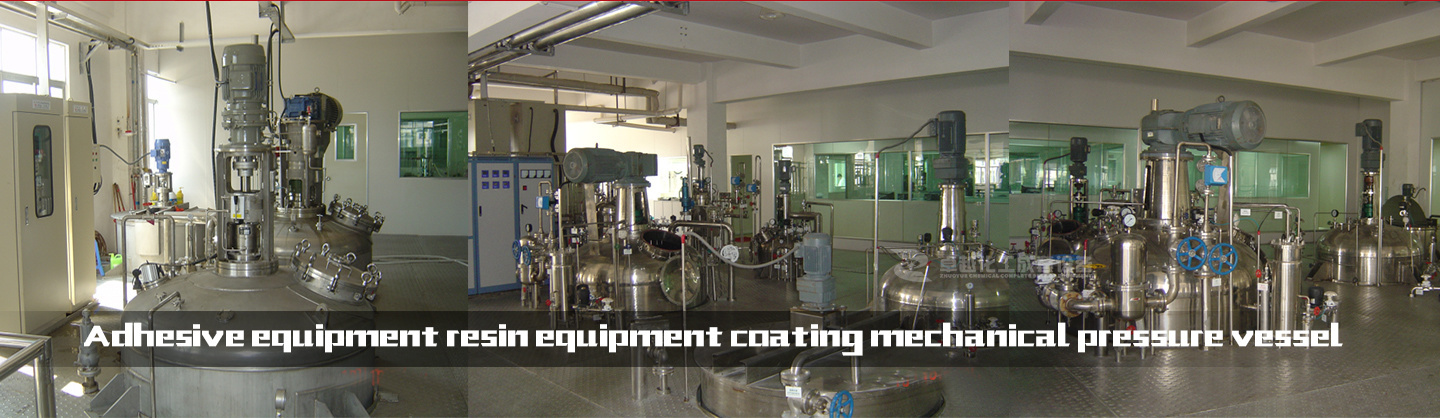

With technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and large domestic companies to provide process package design technical services.

Classification:

Key words:

Product Description

1, with technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and domestic large companies to provide process package design technical services, including:

01. Polyester resin process package design for powder coating.

02. Ink with modified rosin phenolic resin process package design. 03. Design of silicone resin process package for high temperature resistant coating.

04. Water-based acrylic pressure sensitive adhesive process package design. 05. Oily propionic acid pressure sensitive adhesive process package design. 06. Unsaturated polyester resin process package design.

07.502 adhesive process package design,

08. Polyurethane resin adhesive process package design.

09. Room resin process package design.

10. Polyester polyol process package design.

11. Hot melt pressure sensitive adhesive process package design.

12. Alkyd resin process package design.

13. Design of cyclic chlorine resin process package.

14. Rosin modified resin process package design.

15. Acrylic resin process package design.

2, with the implementation of resin and adhesive EPC project general contracting and turnkey project capacity has accumulated a wealth of EPC project management and construction experience.

01. Engineering design: able to provide customers with technical services such as general plan design, equipment layout, process flow diagram pipeline layout, material list, equipment list, pipeline and equipment installation design instructions, etc;

02. With the qualification of pressure vessel, pressure pipe and industrial boiler design, manufacturing and installation, it can provide customers with turnkey engineering services from the whole plant planning and design, production process design, equipment selection and manufacturing, pipeline design and installation, automatic control system development and commissioning, and the whole plant general contracting.

3. Master advanced VOC environmental protection treatment technology: Excellence Company cooperates with Taiwan Company to develop and use Taiwan photoelectric catalyst technology to effectively chemically decompose VOC emitted in the production process of resin, adhesive and coating industry, so as to provide customers with clean and environmentally friendly production environment.

4. Provide customers with energy-saving and consumption-reducing technical services: Through optimized design, provide customers with energy-saving and consumption-reducing heating systems, reduce production costs, and improve product market competitiveness

5. Shorten the construction period and reduce the project cost: in the implementation process of EPC project, the design stage is integrated with procurement and construction, so that the design, procurement and construction links can reasonably cross and connect, so as to shorten the construction period, ensure the quality, save money and provide customers with high-quality and efficient services.

Foshan Excellence Chemical Equipment Co., Ltd. is a high-tech enterprise integrating the design, manufacture, installation and commissioning of chemical machinery and equipment and automation control. Our main products include complete sets of intelligent chip graphene slurry equipment, complete sets of graphene slurry dispersion equipment, complete sets of industrial graphene slurry equipment, complete sets of graphene conductive slurry equipment, complete sets of graphene slurry production equipment, complete sets of lithium battery conductive graphene slurry equipment, complete sets of graphene slurry equipment, complete sets of resin adhesive equipment, complete sets of outer semicircular tube reactor, complete sets of textured true stone paint equipment, etc. Welcome to purchase.

Related Products

online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Copyright©2023 Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. All Rights Reserved www.300.cn SEO Business License