NEWS

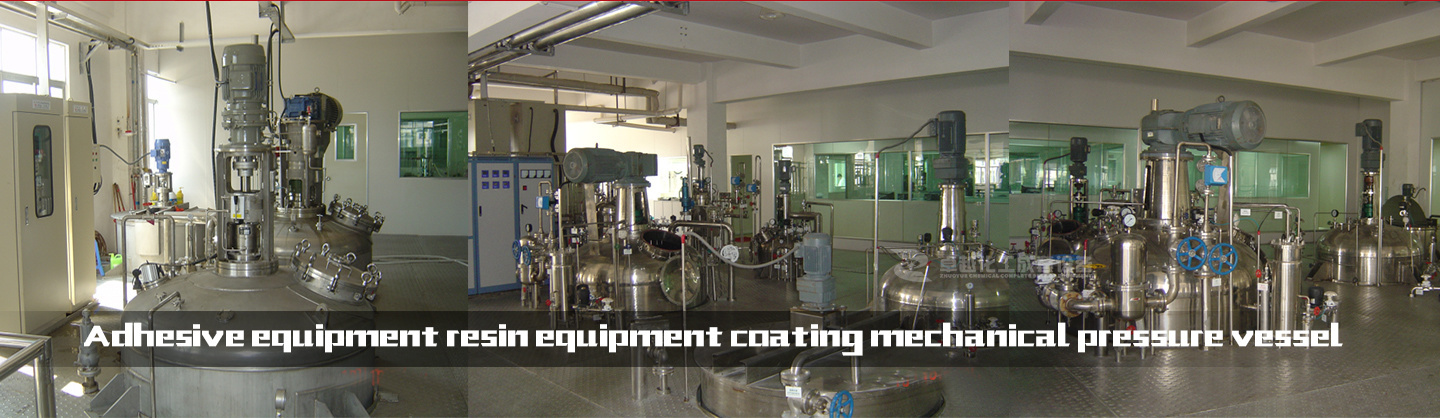

A brief understanding of graphene conductive paste complete sets of equipment

At present, the preparation methods used in the complete set of graphene conductive paste equipment mainly include mechanical method, oxidation method, substrate growth method and liquid phase method. Most of these production technologies and methods have the disadvantages of low output, high energy consumption and poor quality, so they also have certain limitations. After unremitting efforts, a new processing method has been developed. This method can directly integrate graphene high-speed dispersion, crushing, vortex cavitation and shear ultrasound in the liquid phase to achieve continuous dispersion and uninterrupted peeling of graphite flakes. Graphene conductive slurry equipment through mechanical shearing, hydraulic cavitation and other technical means to achieve the production of high quality graphene, by the majority of graphene manufacturers of all ages.

Graphene conductive paste complete equipment is a single-layer, multi-layer and other high-tech equipment for high quality graphene produced by mechanical hydraulic shearing and cavitation exfoliation of graphite flakes. The invention and application of this technology has accelerated the pace of graphene production to a certain extent, and has also strengthened the confidence of graphene manufacturers in large-scale and low-cost production. Moreover, the mechanical hydraulic shearing and graphene conductive slurry production process used in the complete set of equipment has the characteristics of simple operation, safety and reliability, no oxidation, no high temperature resistance, high quality and the like, and is very suitable for high production of graphene.

Graphene conductive paste complete sets of equipment process:

The production process of graphene conductive slurry complete set of equipment: graphite powder, dispersant or surface modifier and water are mixed in a high-shear dispersion mixing and mixing tank for dispersion and mixing, the circulation valve is closed first, and then the connecting valve between the storage tank and the dispersion grinding pump is opened. The graphite solution passes through a fine dispersion mill, a hydraulic shear vortex cavitator, and then enters a high shear cyclone ultrasonic accumulator under pressure. When there is no material in the batching tank, the lower connecting valve is automatically closed, and the circulation valve is opened, so that the graphite solution is continuously circulated, and the sheet is peeled off, so as to achieve the ideal effect of graphene monolayer and monolayer. Graphene conductive paste complete equipment can also use computer control or touch frequency control or automatic control mode.

Copyright©2023 Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. All Rights Reserved www.300.cn SEO Business License