PRODUCTS

Power distribution automatic control system manufacturers

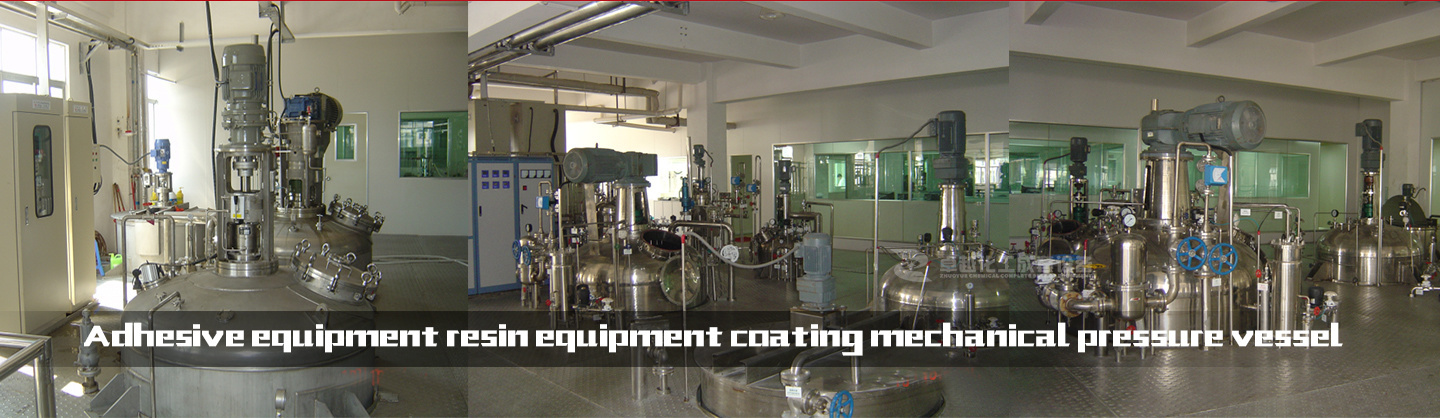

Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. is a high-tech enterprise integrating the design, manufacture, installation and commissioning of chemical machinery and equipment and automation control. The company's main products are automation control system, power distribution control system, PLC automation control system, DCS automation Control system, instrument power cabinet, central control room, touch screen control cabinet, piano instrument control cabinet, etc. Widely used in adhesives, resins, coatings, inks, chemicals, environmental protection, coatings, factories, petroleum, chemicals, rubber, pesticides, dyes, medicine, food, commercial complexes, laboratories, industrial sites and other industries. Products are sold to Beijing, Shandong, Jiangsu, Nanjing, Qingdao, Shanghai, Guangdong, Xi'an, Liaoning, Dalian and other places.

With technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and large domestic companies to provide process package design technical services.

Classification:

Automatic control system

Key words:

Power distribution automatic control system manufacturers

Product Description

With the continuous improvement of labor costs, more and more enterprises pay attention to the field of factory automation, but also to the industry has brought development opportunities. At the same time, how to improve the service level has become a non-standard automation machinery industry's top priority. The number of non-standard automation mechanized enterprises in China is large, but the scale is small, the technology is backward, and the competition is homogeneous. How to participate in the competition in this industry has become a challenge.

Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. is a high-tech enterprise integrating the design, manufacture, installation and commissioning of chemical machinery and equipment and automation control. The company's main products are automation control system, power distribution control system, PLC automation control system, DCS automation Control system, instrument power cabinet, central control room, touch screen control cabinet, piano instrument control cabinet, etc. Widely used in adhesives, resins, coatings, inks, chemicals, environmental protection, coatings, factories, petroleum, chemicals, rubber, pesticides, dyes, medicine, food, commercial complexes, laboratories, industrial sites and other industries. Products are sold to Beijing, Shandong, Jiangsu, Nanjing, Qingdao, Shanghai, Guangdong, Xi'an, Liaoning, Dalian and other places.

The power transformation and distribution monitoring system is used for monitoring and management, which can be connected to intelligent power monitoring instruments, low-voltage circuit breakers with intelligent interfaces, medium-voltage comprehensive protection relays, transformers, DC panels, etc. to realize remote control, telemetry and remote signaling functions, and real-time collection and display of various operating switch states and power parameters of the system, which can completely grasp the real-time operating state of the power transformation and distribution system, find faults in time and make corresponding decisions and processing, at the same time, the on-duty management personnel can carry out load analysis, reasonable scheduling, remote control closing and opening, peak and valley filling according to the operation of the power transformation and distribution system, so as to realize the modern operation management of the power transformation and distribution system.

The power distribution monitoring system has comprehensive functions such as real-time monitoring of electrical parameters, abnormal accident alarm, event recording and printing, sorting and printing of statistical reports, electric energy cost management and load monitoring, etc., so that the equipment can operate according to the best working conditions and save energy. The intelligent power distribution monitoring and management system is adopted to make the power supply system more safe, reasonable and economical operation, and improve the reliability of the power supply and distribution system. It is suitable for monitoring and management of substation and distribution system in medium and low voltage substations, factories, buildings and residential areas.

Distribution automation control system is widely used in industry, agriculture, military, scientific research, transportation, commerce, medical, service and family. The use of automation technology can not only liberate people from heavy manual labor, part of mental labor and harsh and dangerous working environment, but also greatly improve the production efficiency and production capacity of enterprises, and reduce the cost of unnecessary losses caused by workers' wages and manual operation.

The company provides customers with energy-saving and consumption-reducing technical services: through optimized design, it provides customers with energy-saving and consumption-reducing heating systems, reduces production costs, and improves product market competitiveness. Shorten the construction period and reduce the project cost: in the implementation process of EPC project, the design stage is integrated with procurement and construction, so that the design, procurement and construction links can be reasonably crossed and connected, so as to shorten the construction period, ensure the quality, save money, and provide customers with high-quality and efficient services.

1, with technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and domestic large companies to provide process package design technical services, including:

01. Polyester resin process package design for powder coating.

02. Ink with modified rosin phenolic resin process package design. 03. Design of silicone resin process package for high temperature resistant coating.

04. Water-based acrylic pressure sensitive adhesive process package design. 05. Oily propionic acid pressure sensitive adhesive process package design. 06. Unsaturated polyester resin process package design.

07.502 adhesive process package design,

08. Polyurethane resin adhesive process package design.

09. Room resin process package design.

10. Polyester polyol process package design.

11. Hot melt pressure sensitive adhesive process package design.

12. Alkyd resin process package design.

13. Design of cyclic chlorine resin process package.

14. Rosin modified resin process package design.

15. Acrylic resin process package design.

2, with the implementation of resin and adhesive EPC project general contracting and turnkey project capacity has accumulated a wealth of EPC project management and construction experience.

01. Engineering design: able to provide customers with technical services such as general plan design, equipment layout, process flow diagram pipeline layout, material list, equipment list, pipeline and equipment installation design instructions, etc;

02. With the qualification of pressure vessel, pressure pipe and industrial boiler design, manufacturing and installation, it can provide customers with turnkey engineering services from the whole plant planning and design, production process design, equipment selection and manufacturing, pipeline design and installation, automatic control system development and commissioning, and the whole plant general contracting.

3. Master advanced VOC environmental protection treatment technology: Excellence Company cooperates with Taiwan Company to develop and use Taiwan photoelectric catalyst technology to effectively chemically decompose VOC emitted in the production process of resin, adhesive and coating industry, so as to provide customers with clean and environmentally friendly production environment.

4. Provide customers with energy-saving and consumption-reducing technical services: Through optimized design, provide customers with energy-saving and consumption-reducing heating systems, reduce production costs, and improve product market competitiveness

5. Shorten the construction period and reduce the project cost: in the implementation process of EPC project, the design stage is integrated with procurement and construction, so that the design, procurement and construction links can reasonably cross and connect, so as to shorten the construction period, ensure the quality, save money and provide customers with high-quality and efficient services.

Foshan Excellence Chemical Equipment Co., Ltd. is a high-tech enterprise integrating the design, manufacture, installation and commissioning of chemical machinery and equipment and automation control. Our main products include complete sets of intelligent chip graphene slurry equipment, complete sets of graphene slurry dispersion equipment, complete sets of industrial graphene slurry equipment, complete sets of graphene conductive slurry equipment, complete sets of graphene slurry production equipment, complete sets of lithium battery conductive graphene slurry equipment, complete sets of graphene slurry equipment, complete sets of resin adhesive equipment, complete sets of outer semicircular tube reactor, complete sets of textured true stone paint equipment, etc. Welcome to purchase.

Related Products

online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Copyright©2023 Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. All Rights Reserved www.300.cn SEO Business License