PRODUCTS

Silicone resin reactor

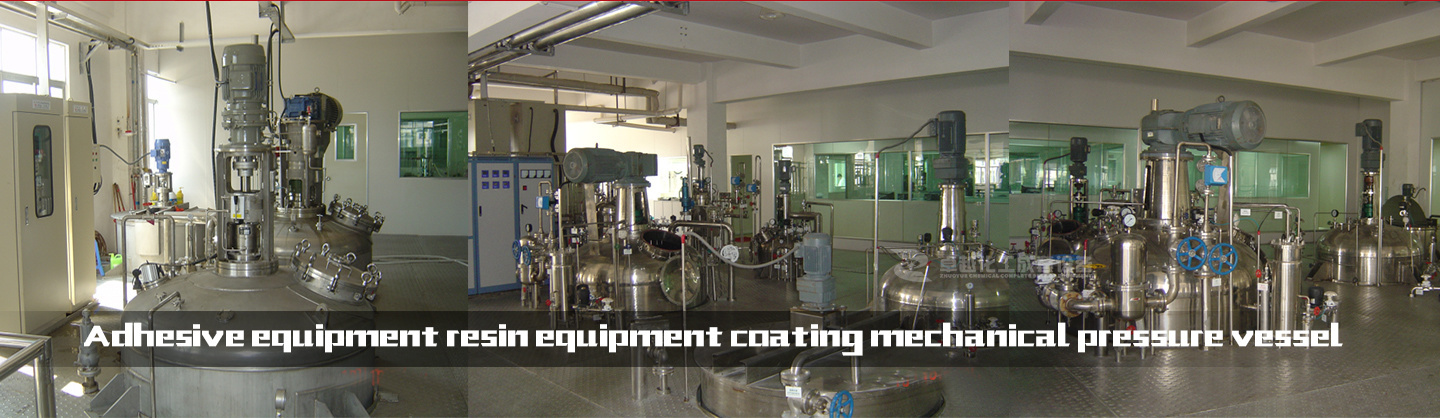

Foshan Excellence Chemical Equipment Co., Ltd. is a chemical machinery and equipment and automation control system manufacturers. The company's reactor products are silicone resin reactor, outer semicircular tube reactor, outer semicircular tube reactor, rosin modified phenolic resin reactor, water-based pressure sensitive adhesive reactor, biological fermentation reactor, hot melt pressure sensitive adhesive reactor, urea-formaldehyde resin reactor, electric heating reactor, white latex reactor, 35KL polyester resin reaction, polyester resin reactor, 25KL polyester resin reactor, 502 glue reactor, etc. Resin reactor has been in Guangdong, Chengdu, Hunan, Dongguan, Guangxi, Shandong, Sichuan, Shenyang, Chongqing, Guizhou, Yunnan, Beijing, a number of production enterprises in normal operation.

With technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and large domestic companies to provide process package design technical services.

Classification:

Reaction equipment

Key words:

Silicone resin reactor

Product Description

Foshan Excellence Chemical Equipment Co., Ltd. is mainly engaged in electric heating reaction kettle, outer semicircular tube reaction kettle, outer semicircular tube reaction kettle, rosin modified phenolic resin reaction kettle, water-based pressure sensitive adhesive reaction kettle, biological fermentation reaction kettle, hot melt pressure sensitive adhesive reaction kettle, urea formaldehyde resin reaction kettle and other chemical machinery equipment. Reactor is widely used in petroleum, chemical, rubber, pesticides, dyes, medicine and food and other fields, is used to complete the vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation process pressure vessel. It has been operating normally in many production enterprises, schools and laboratories in Guangdong, Chengdu, Hunan, Dongguan, Guangxi, Shandong, Sichuan, Shenyang, Chongqing, Guizhou, Yunnan and Beijing.

Reaction equipment products silicone resin reactor, outer semicircular tube reactor, outer semicircular tube reactor, rosin modified phenolic resin reactor, aqueous pressure sensitive adhesive reactor, biological fermentation reactor, hot melt pressure sensitive adhesive reactor, urea-formaldehyde resin reactor, electric heating reactor, white latex reactor, 35KL polyester resin reaction, polyester resin reactor, 25KL polyester resin reactor, 502 glue reactor, etc.

The generalized understanding of the reactor is a container with physical or chemical reactions. Through the structural design and parameter configuration of the container, the heating, evaporation, cooling and low-speed mixing functions required by the process are realized. Reactors are widely used in petroleum, chemical, rubber, pesticides, dyes, medicine, food and other fields. They are pressure vessels used to complete vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation and other processes, such as reactors, reaction pots, decomposition pots, polymerization kettles, etc. The materials are generally carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel, Inconel) alloys and other composite materials.

Organic resin reactor for the production of unsaturated polyester resin, rosin resin, epoxy resin, phenolic resin, alkyd resin, paint and adhesive key equipment. Resin reactor has been in Guangdong, Chengdu, Hunan, Dongguan, Guangxi, Shandong, Sichuan, Shenyang, Chongqing, Guizhou, Yunnan, Beijing, a number of production enterprises in normal operation.

Resin reactor is a typical main reaction equipment in the production of chemical raw materials, which is widely used in the production of chemical raw materials. A plurality of materials are dispersed and mixed by stirring, heating, and cooling to carry out reaction polymerization. The structure of phenolic resin reactor is generally composed of kettle body, transmission device, stirring device, heating device, cooling device and sealing device. Resin reactor has been in Guangdong, Chengdu, Hunan, Dongguan, Guangxi, Shandong, Sichuan, Shenyang, Chongqing, Guizhou, Yunnan, Beijing, a number of production enterprises in normal operation.

Scope of application of resin reaction kettle

According to the reaction temperature, the resin reactor is divided into high temperature resin reactor (150 ℃-300 ℃) and low temperature resin reactor (60 ℃-150 ℃). Resin reactor is used for the production of unsaturated polyester resin, phenolic resin, epoxy resin, ABS resin, paint the key equipment. The complete set of resin equipment is composed of reaction pot, vertical fractionating column, horizontal condenser, water reservoir, oil overflow tank, pipeline (for dilute kettle), etc. The contact part of the complete set of equipment and materials is made of stainless steel. The stainless steel coil can be set in the reaction kettle or the stainless steel coil can be set in the jacket.

Resin definition and classification

Broadly speaking, any polymer that can be used as a raw material for plastic products is called a resin. Synthetic resin refers to a resin product obtained by chemical synthesis of simple organic matter or chemical reaction of some natural products.

1. Classification by resin synthesis reaction:

Resins can be divided into addition polymers and condensation polymers. The addition polymer refers to a polymer prepared by addition polymerization, and the chemical formula of its chain structure is the same as the molecular formula of the monomer, such as polyethylene, polystyrene, polytetrafluoroethylene, etc. The condensation polymer refers to a polymer prepared by condensation polymerization, and the chemical formula of the structural unit is different from the molecular formula of the monomer, such as phenolic resin, polyester resin, polyamide resin, etc.

2. According to the resin molecular main chain composition classification:

Resins can be classified as carbon-chain polymers, hetero-chain polymers, and elemental organic polymers.

The carbon chain polymer refers to a polymer whose main chain is composed entirely of carbon atoms, such as polyethylene, polystyrene, etc.

1, with technologically advanced resin and adhesive process package design capabilities, long-term for multinational companies and domestic large companies to provide process package design technical services, including:

01. Polyester resin process package design for powder coating.

02. Ink with modified rosin phenolic resin process package design. 03. Design of silicone resin process package for high temperature resistant coating.

04. Water-based acrylic pressure sensitive adhesive process package design. 05. Oily propionic acid pressure sensitive adhesive process package design. 06. Unsaturated polyester resin process package design.

07.502 adhesive process package design,

08. Polyurethane resin adhesive process package design.

09. Room resin process package design.

10. Polyester polyol process package design.

11. Hot melt pressure sensitive adhesive process package design.

12. Alkyd resin process package design.

13. Design of cyclic chlorine resin process package.

14. Rosin modified resin process package design.

15. Acrylic resin process package design.

2, with the implementation of resin and adhesive EPC project general contracting and turnkey project capacity has accumulated a wealth of EPC project management and construction experience.

01. Engineering design: able to provide customers with technical services such as general plan design, equipment layout, process flow diagram pipeline layout, material list, equipment list, pipeline and equipment installation design instructions, etc;

02. With the qualification of pressure vessel, pressure pipe and industrial boiler design, manufacturing and installation, it can provide customers with turnkey engineering services from the whole plant planning and design, production process design, equipment selection and manufacturing, pipeline design and installation, automatic control system development and commissioning, and the whole plant general contracting.

3. Master advanced VOC environmental protection treatment technology: Excellence Company cooperates with Taiwan Company to develop and use Taiwan photoelectric catalyst technology to effectively chemically decompose VOC emitted in the production process of resin, adhesive and coating industry, so as to provide customers with clean and environmentally friendly production environment.

4. Provide customers with energy-saving and consumption-reducing technical services: Through optimized design, provide customers with energy-saving and consumption-reducing heating systems, reduce production costs, and improve product market competitiveness

5. Shorten the construction period and reduce the project cost: in the implementation process of EPC project, the design stage is integrated with procurement and construction, so that the design, procurement and construction links can reasonably cross and connect, so as to shorten the construction period, ensure the quality, save money and provide customers with high-quality and efficient services.

Foshan Excellence Chemical Equipment Co., Ltd. is a high-tech enterprise integrating the design, manufacture, installation and commissioning of chemical machinery and equipment and automation control. Our main products include complete sets of intelligent chip graphene slurry equipment, complete sets of graphene slurry dispersion equipment, complete sets of industrial graphene slurry equipment, complete sets of graphene conductive slurry equipment, complete sets of graphene slurry production equipment, complete sets of lithium battery conductive graphene slurry equipment, complete sets of graphene slurry equipment, complete sets of resin adhesive equipment, complete sets of outer semicircular tube reactor, complete sets of textured true stone paint equipment, etc. Welcome to purchase.

Related Products

online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Copyright©2023 Foshan Zhuoyue Chemical Complete Equipment Co., Ltd. All Rights Reserved www.300.cn SEO Business License